The manifold is the central part of the underfloor heating system. It is where the pipework from each room comes together and where the supply of hot water from the heat source is fed into the underfloor heating pipes..

underfloor heating manifold

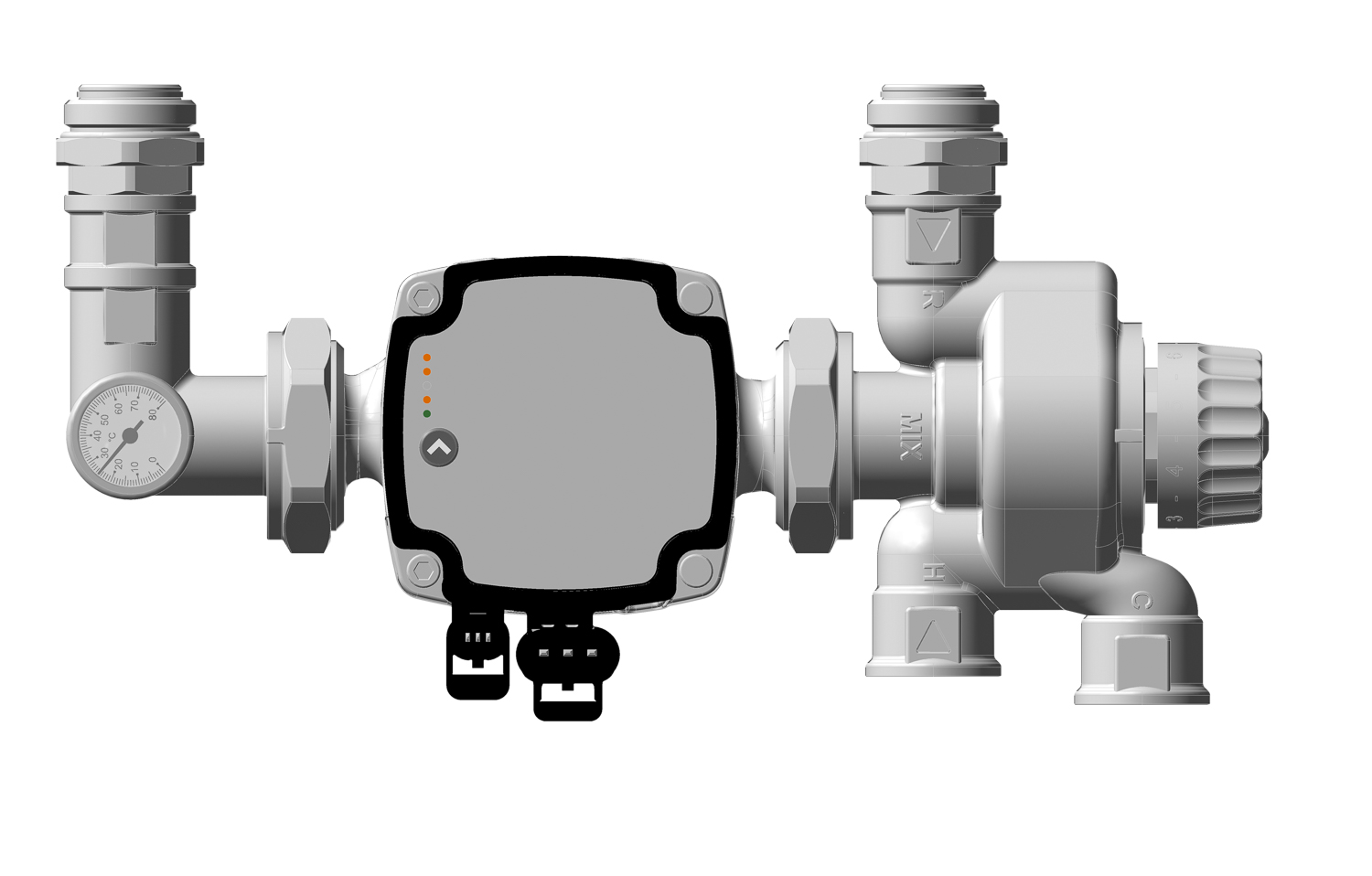

Manifold

Temperature gauge

The Incognito underfloor heating manifolds are made of stainless steel and designed to be used with wet underfloor heating systems. The manifold is manufactured from pressed stainless steel, and is run through stringent testing procedures throughout the manufacturing process. Following completion, every manifold is tested to 6 bar pressure (typical operating pressure would be less than 3 bar). As standard the manifold comes with a manual air vent, which can easily be upgraded to an automatic version. A fill and drain point with hose connector is located on both the flow and return bar. Each loop on the flow bar has a flow meter, to clearly indicate the flow rate achieved in each loop. These meters are used to balance the system at commissioning stage, as per the underfloor heating design. Each loop on the return bar has a valve to open or close the loop, controlled by an actuator valve, which responds to the call for heat from a room thermostat.

Pump Blender Unit

In an underfloor heating system, the water is pumped and blended locally at the manifold. This is done via a combined pump/blender unit, which is fixed to one end of the manifold.

Incognito offer a unique pump/blender unit, in the form of our new Ambiente CircoMax. The blender valve has a greater temperature setting, ranging from 25-80 degrees, which can be left running at a low flow temperature without threatening sensitive floor coverings. The manifold and pump set is extremely flexible and allows the pump to be mounted on the left or right hand side or in a number of other configurations.